I have another blog that hasn't been updated in a few months, but this one is devoted to my project to build a modular electric bicycle system for my Social Studies class. I chose this project not only because it thought it would be fun to build and ride, but also because climate change and air pollution are going to be increasingly large problems in the coming years. As huge numbers of people, particularly in China and India, rise out of poverty, they need a mode of transportation and cars, even electric ones, are much too heavy and wasteful for everyone to have. As prices have dropped over the last couple of years, electric bicycles have taken off in developing nations as a cheap method of personal transportation, in large part because of the restrictions on the numbers of gas vehicles that can enter Chinese cities each day. From what I've seen, there is an absence of this type of electric bike, that is cheap, relatively easy to install, powerful, and efficient. The final reason I am doing this project is that I think I will learn a lot about the designing and building process, and this is something that I intend to actually use, so hopefully I will also learn how to make this bike more reliable than my projects have been in the past.

There are a lot of electric bicycles in the world now, from the commercial bikes with custom-designed frames to the front wheels you can buy with motor and battery integrated into the hub. I wanted to make it modular so that it is possible to add the motor, gearbox, and batteries to a bike fairly easily and without permanently damaging it, making it accessible to more people and allowing components or even the whole bike to be upgraded easily. The vast majority of ebikes sold today use hub motors, which have the motor built into the wheel because that is easy and cheap to implement, but after a lot of research, I found a different solution that made a lot more sense.

|

| Specialized Turbo S with a hub motor in the rear wheel and the battery hidden in the frame. Specialized.com |

|

| Copenhagen Wheel with everything in the hub. Uncrate.com |

|

| Two large brushless outrunners. Charles Guan |

|

| A homemade mid-drive bicycle. ElectricBike.com |

|

Brose 450w mid-drive with belt. ElectricBike.com

|

They nearly all have the battery built into the frame and the motor and reduction system built into the crank spindle (called the bottom bracket), things that are not possible without a custom frame.

|

| Trek/Bosch mid-drive with gears. ElectricBike.com |

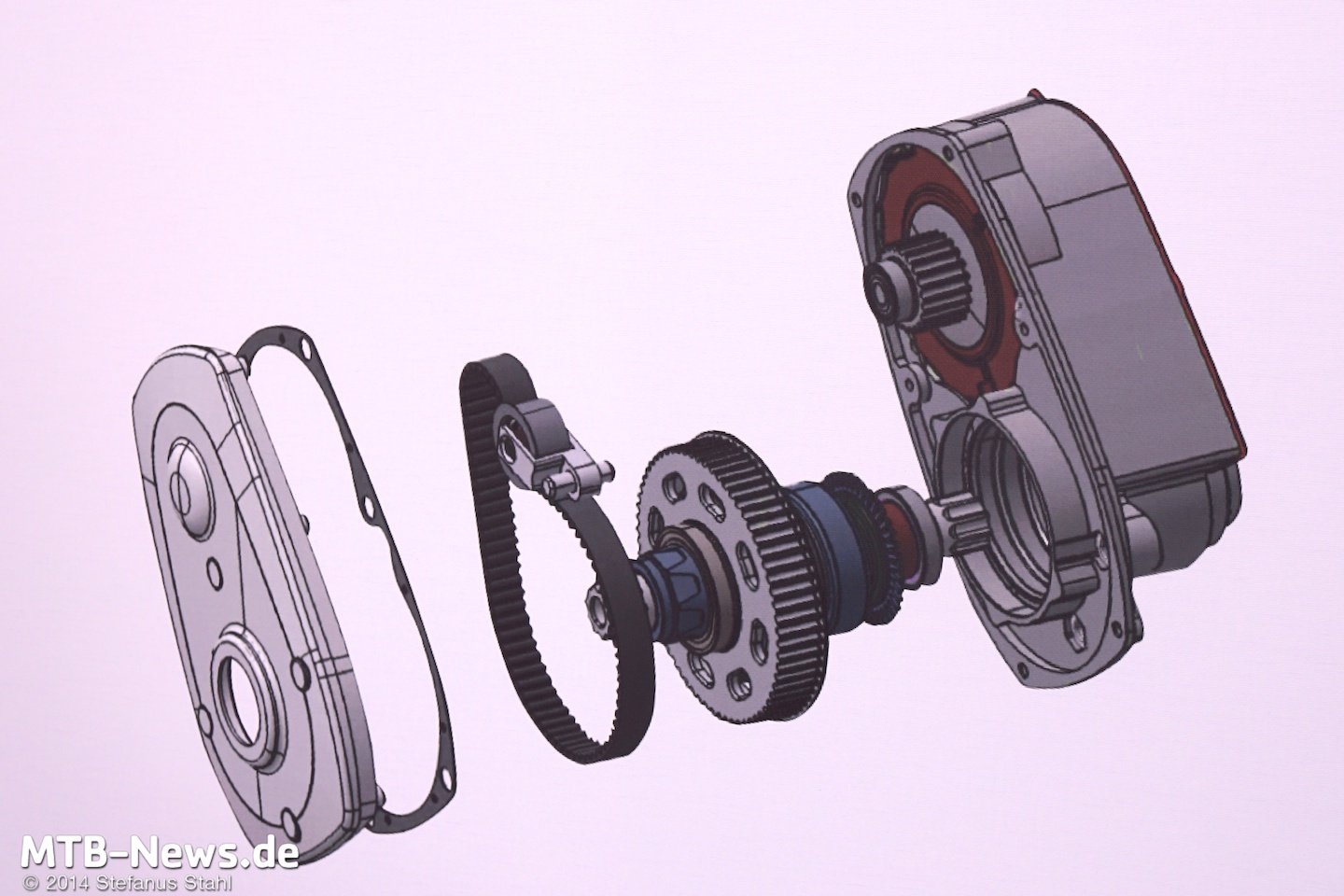

Only a few have released details, but it seems there is a split between using gears or belts for the reduction inside the bottom bracket, with gears being stronger and smaller while belts are cheaper, quieter, and more resistant to dirt and grime.

|

| Exploded CAD view of Brose belt reduction. MTB-News.de |

|

| Bosch gearbox cutaway view. ElectricBike.com |

The design in my head and parts list has continued to evolve, and I made some simple CAD models with OpenSCAD, which is horribly inferior for most things compared to software like Solidworks which I learned at UVM, but I need to make a better CAD model so I know everything fits and have something to work off of. This means either getting Windows to work on my desktop so I can install and learn Autodesk Inventor or spending lots of time in the UVM computer lab. I also have a spreadsheet for listing the parts and costs as well as doing gearing and speed calculation.

I need to figure out whether to use Lithium-Ion batteries, which are lighter, more powerful, and store more energy, or Lead-Acid batteries, which I got for free, and also whether to upgrade the chainrings and freewheel or leave the current ones. I'll probably just make it with the cheapest components possible and upgrade later if it's not good enough.

Right now I have a small pile of parts, shown below in my first attempt at knolling. The square aluminum extrusion is the frame for the motor and reduction system, with shaft collars as well as radial and thrust bearings on top. I have five lead acid batteries, 12V 7.2Ah, from old UPS's at my dad's work which have unknown life left, and will choose the best three to use. Also shown is my controller, a Mini Jasontroller from the supremely cheap and somewhat shady ELifeBike.com, and my throttle on the right. Finally, there's a precharge resistor and switch.

In terms of actually building, I could work on either the electrical or mechanical side first, because neither depend on the other. The electrical side just needs the motor and some large connectors for the power before I can get the motor running. The mechanical side, on the other hand, needs the chain, sprockets, shaft, pulleys, and belt, and I need to get some holes and slots accurately cut in an aluminum extrusion which will probably require a machine shop.

But first, another blog post about all the awesome stuff I saw at the MIT Mini Maker Faire!

No comments:

Post a Comment